We are a plastic recycling machine manufacturer, specializing in providing machines for waste plastic recycling in factories. If you are a manufacturer of plastics (plastic bags, plastic gloves, plastic pipes), or a manufacturer of recycled waste plastics (such as films, bottles, non-woven fabrics), then we can provide you with a granulator to recycle plastics.. Recycled high-quality plastic particles can be directly added to the film production line, and the added proportion is 30% to 100%.

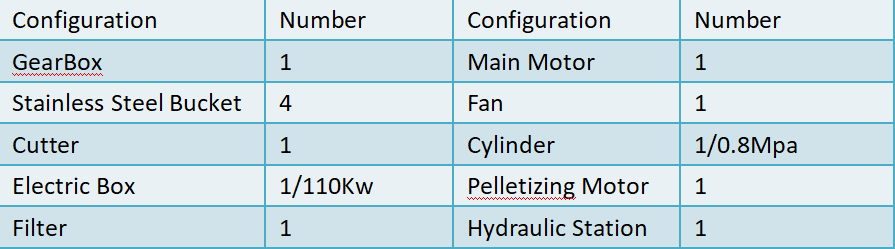

Plastic Recycling Machine Configuration

What material SINSANDA can recycle it?

SINSANDA has successfully recycled the materials listed in the table below. However, please note that this is not an exhaustive list, and if you wish to recycle materials not mentioned here, do not hesitate to consult us. We have the expertise to handle most types of materials.

| PE | PP | PET |

| PE+nylon | PLA | LDPE |

| EVA | PVC | TPU |

| PABT | HDPE | BOPP |

| Non-woven Fabric | Breathable Film | PE+PLA |

What forms of plastic can SINSANDA recycle

SINSANDA can recycle the following forms of plastic, generally if it is a film, it can be fed directly, and hard materials such as pipes have a better effect after crushing. Dirt needs to be cleaned.

| Roll Plastic Film | Scrap Plastic | Post customer Plastic |

| Garbage Plastic | Plastic Pipe | Used Plastic |

Recycling Progress

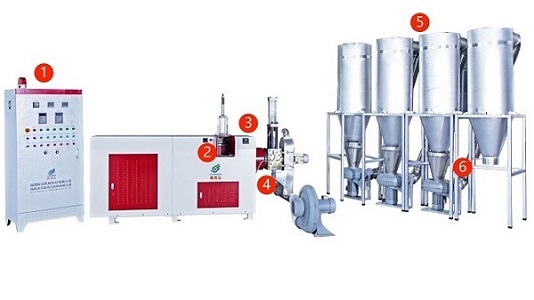

1. The machine starts functioning as soon as the electric control cabinet is turned on, and power is supplied to the pelletizer.

2. The feed port can feed manually or through an external conveyor belt.

3. Through the physical extrusion of the screw and frictional heat generation, the plastic becomes semi-solid.

4. Cutting the plastic into pellets is primarily achieved with a blade, while a filter can be incorporated to remove any impurities.

5. Rapid cooling of the pellets is facilitated by the air-cooling component.

6. The pellets are gathered at the pelletizer's outlet.

Our Advantage

1.The pelletizer has reasonable price and high cost performance, with competitive advantage in the same industry.

2.The pelletizer is easy to maintain, with compact structure, small footprint, easy to clean and replace parts.

3.The pelletizer does not need heating, saving energy consumption and reducing production cost.

4.The pelletizer has high output, and can customize different specifications and capacities of pelletizers according to customer needs.

5.The pelletizer can handle various materials, such as PE, PP, PET, ABS, etc., with strong adaptability and meeting different customer needs.

After Sale

We are pleased to promise you that our after-sales service includes one year of free maintenance and a lifetime warranty. Our professional team can visit your factory for installation and debugging when needed, and provide detailed operation instructions.

Packaging process

1.To ensure that the goods are not damaged during transportation, we utilize wooden crates or frames as packaging materials. The woodwork has been previously fumigated; if you require a fumigation certificate, please notify us in advance.

2.For high-value devices, we use appropriate fillers like foam plastics to protect the goods from any vibration and impact while in transit.

3.It's essential to attach any necessary labels and markings on the package, including the product name, quantity, weight, production date, and serial number. Please note that the serial number is particularly important when installing remotely since it serves as the basis for assembly.

Transport Information

About Delivery Time

After signing the contract, we will send the goods to the designated port within 45 days. Please contact the freight forwarder in advance.

About Delivery

We support FOB

About Payment method

We Support T/T

If you have other payment needs or shipping needs, you can also contact our staff!